Manufacturing Management

SMURPS ERP empowers you to manage manufacturing from planning to delivery, with real-time visibility and total control in one easy-to-use system.

Manufacturing Management

SMURPS ERP empowers you to manage manufacturing from planning to delivery, with real-time visibility and total control in one easy-to-use system.

Made for Manufacturers,

Scalable for Every Stage of Growth

Gain full control over your production processes from raw materials to finished goods. SMURPS ERP seamlessly connects planning, inventory, procurement, sales and finance in one unified platform. Recognised as one of the top Manufacturing Management System solution in Malaysia. Built for manufacturers across both discrete and process industries, it provides real-time visibility into production work orders, shop floor operations, material traceability, and quality control. With tools to streamline assembly, manage formulations, optimize resource utilization, and minimize waste, it helps manufacturers stay efficient and competitive in a fast-changing market.

Production Ordering and Execution

Align demand and capacity using advanced MRP tools and flexible planning workflows.

Multi-Level Bill of Materials (BOM)

Support complex product structures with dynamic, multi-tier BOM capabilities.

Just-in-Time & Make-to-Order

Optimise production efficiency and reduce waste with lean manufacturing workflows.

Workstation-Based Routing & Orders

Configure and manage production flows based on real-world routing and workstations.

Inventory & Material Tracking

Monitor materials and finished goods in real-time, with batch and serial tracking.

The Core of SMURPS Manufacturing Management

Shaping Manufacturing into a Streamlined Powerhouse

Automated Stock Reservations

Automatically allocate materials to jobs and prevent shortages or bottlenecks.

Work Order Management

Create, track, and close work orders with real-time updates from the shop floor.

Production Costing & Profitability

Capture and compare planned vs actual labour, overhead, and material costs.

Quality Control & Compliance

Set custom quality checks and ensure compliance at every production stage.

Seamless ERP Integration

Sync your production with sales, procurement, inventory, and finance in real-time.

Flexible. Future-Ready. Field-Proven.

Why SMURPS ERP?

Industry Versatility

SMURPS ERP supports a wide range of industries, including metal stamping, plastic extrusion, chemicals, food processing, and precision machining.

Role-Based Access & UI

Provide secure, role-specific access with intuitive interfaces and mobile-ready dashboards for clear, real-time visibility.

Real-Time Insight

Make faster decisions with real-time data from planning to production.

Cloud-Ready & Scalable

Easily manage multiple sites with centralised cloud access and updates.

Versatile. Scalable. Industry Ready.

Made to Fit Every Manufacturing Environment

SMURPS ERP, the leading Manufacturing Management System in Malaysia, designed to adapt to your production workflows and scale with your business—from small enterprises to multi-plant operations in industries such as food processing, engineering, and metal fabrication.

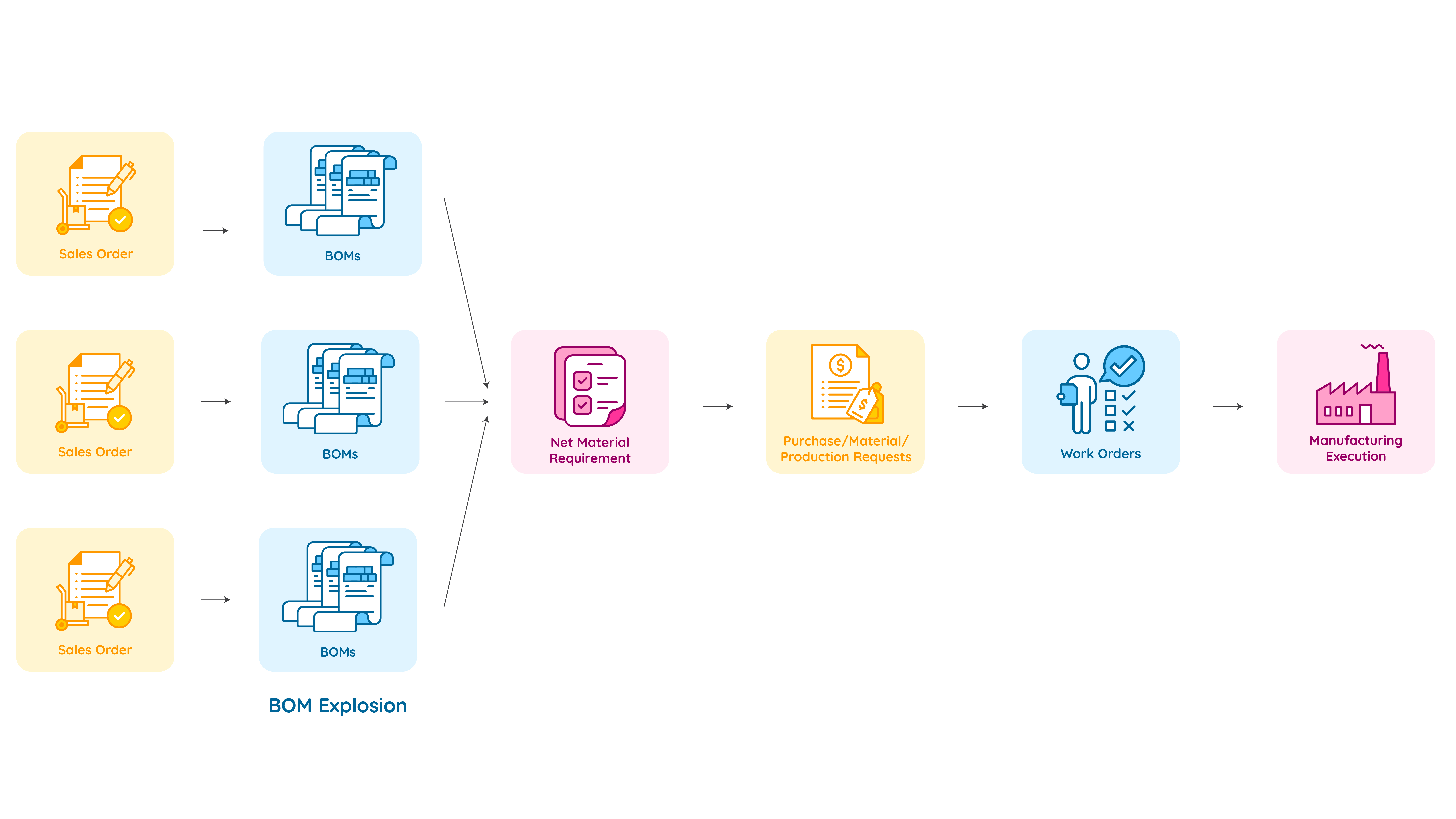

Materials Requirements Planning (MRP)

Smarter Material Planning with SMURPS ERP

Ensure that every production run has the right materials at the right time. SMURPS ERP, includes a complete MRP engine that forecasts material needs, checks inventory availability, and suggests optimal purchasing and production actions.

Sales Order & Forecast-Driven Planning

Generate material demand based on Sales Orders, or Material Requests.

Multi-Level BOM Explosion

Automatically break down BOMs into sub-assemblies and raw materials to compute exact requirements.

Real-Time Stock Visibility

MRP considers on-hand, reserved, WIP, and incoming stock to determine true net requirements.

Automatic Material Planning (MRP Run)

Use the Production Planning Tool or MRP Run to automatically generate:

- Purchase Requests / Purchase Orders

- Material Requests

- Production Orders (Work Orders)

Supplier Lead Times

System respects supplier lead times and adjusts material planning dates accordingly.

Why MRP Software Matters for Manufacturers

Streamline Production; Cut Waste; Deliver On Time

Implementing MRP system through SMURPS ERP gives manufacturers the control and insight they need to keep production running smoothly:

- Prevent material shortages that cause production delays

- Improve inventory turnover and reduce excess stock

- Ensure every Work Order has materials ready before production starts

- Enable purchasing teams to act proactively with accurate demand signals

- Automate planning of sub-assemblies and multi-level BOM manufacturing

- Boost on-time delivery by aligning materials with production schedules

Build More, Waste Less with SMURPS!

Get in touch to see how you can maximise output and minimise waste with one powerful system.